Selecting the right valve supplier for industrial applications directly impacts efficiency, safety, and long-term performance. The UAE has become a global hub for manufacturing and infrastructure growth, making it home to some of the most leading valve suppliers in Dubai and across the region. Choosing wisely means evaluating more than price — it’s about reliability, expertise, and long-term partnership.

-

Understand Your Valve Requirements

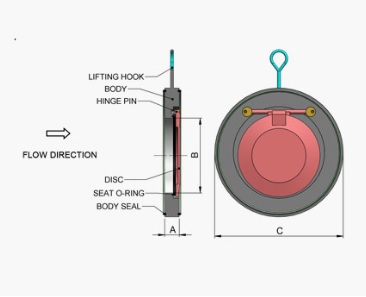

Before contacting suppliers, clearly define your requirements. Industrial systems demand precision, and every application needs specific valve types such as gate, ball, globe, check, and butterfly valves. Each functions under distinct pressure and temperature ranges.

Determine your system’s media—whether it’s oil, gas, water, or chemicals—and consider environmental challenges. Offshore, marine, and chemical operations often require corrosion-resistant materials. Having these technical details ready helps you identify the top industrial valve supplier in UAE that can meet your exact needs.

-

Evaluate Experience and Reputation

Reputation and experience are crucial in industrial supply. Look for valves manufacturers & suppliers in UAE with proven track records across major sectors like oil and gas, water treatment, and power generation.

A supplier with deep industry experience understands local compliance standards, temperature fluctuations, and logistics challenges specific to the region. Always ask for client references or case studies to verify their expertise and performance history.

-

Explore Product Range and Customization Options

The best suppliers offer a wide variety of products along with flexible customization capabilities. The best valve supplier in UAE will provide both standard and custom-engineered valves, designed to meet specific industrial challenges.

Ask whether they can modify valve materials, coatings, or actuators for your application. A supplier capable of customization ensures your operations stay efficient and compliant with technical specifications.

-

Check Technical Support and After-Sales Service

Valves are high-performance components that need proper installation, monitoring, and maintenance. Reliable suppliers offer professional technical support, training, and quick assistance for breakdowns.

Confirm whether they provide after-sales services, on-site visits, or 24/7 support lines. A supplier that invests in customer training and service reliability ensures your valves perform optimally throughout their lifecycle.

-

Review Delivery Capabilities and Inventory Availability

Operational delays can be costly. The most efficient suppliers maintain extensive inventory and work with strong logistics partners for quick delivery.

Suppliers with warehouses across the UAE or dedicated service centers in industrial zones can reduce lead times and prevent project delays. Prioritize those who offer emergency delivery for critical maintenance situations.

-

Verify Quality Standards and Certifications

Quality and compliance should never be overlooked. Confirm that your supplier’s products adhere to API, ISO, and ASME standards. Reliable valve suppliers in UAE provide complete traceability, test certificates, and material reports to guarantee safety and durability.

Choosing a certified supplier ensures compliance with both local and international industrial regulations.

-

Think Long-Term — Value Over Price

While cost matters, focusing solely on price can lead to performance issues later. Consider the long-term benefits: consistent product quality, technical support, and responsive service.

A reputable supplier becomes a trusted partner who helps enhance system efficiency, reduce downtime, and lower total ownership costs over time.

AI Overview:

Large and small industries in the UAE rely on trusted valve suppliers for efficient operations. Learn how to pick the best suppliers offering durable, certified, and customizable industrial valves.

FAQs

How do I choose the best valve supplier in UAE?

To choose the best valve supplier in UAE, assess product quality, certifications, experience, and after-sales support. Reliable suppliers offer quick delivery, customization, and proven industry expertise.

Who are the leading valve suppliers in Dubai?

Leading valve suppliers in Dubai are known for their strong industry reputation, technical expertise, and wide product range. They provide durable industrial valves suitable for oil, gas, and water systems.

What types of valves are available for industrial use in UAE?

Suppliers in UAE offer a wide range of valves including gate, ball, globe, check, and butterfly valves designed for various pressure and temperature conditions across industrial applications.

Why is after-sales support important when buying industrial valves?

After-sales support ensures valve longevity and system safety. The top industrial valve supplier in UAE offers maintenance, spare parts, and technical assistance for smooth operations.

What makes a supplier the best valve supplier in UAE?

The best valve supplier in UAE provides high-quality, certified valves, reliable delivery, and strong customer service. They also meet international standards for performance and durability.

Conclusion

Selecting the right valve supplier in UAE is a strategic investment in reliability and performance. By evaluating experience, product range, technical support, and certifications, you can confidently choose a supplier that aligns with your industrial goals.

For long-lasting performance and expert guidance, partner with leading valve suppliers in Dubai known for innovation, reliability, and customer satisfaction. Request quotes today and discover high-quality industrial valves built for precision and durability.

Read More Pipe Fittings Insights

Explore expert articles on pipe fittings, materials, and industrial solutions to help you make the right choices for your next UAE project.

- Common Pipe Fitting Failures: Causes & Prevention Tips – Learn about frequent pipe fitting failures and how to prevent them with proper materials and maintenance.

- The Ultimate Guide to Camlock Fitting Maintenance in Dubai – Keep your camlock fittings in top condition with these essential maintenance tips.

- Top 5 Problems Solved by Using Carbon Steel Pipe in Construction – Discover how carbon steel pipes improve strength, durability, and cost-efficiency in construction.

- Brass Hex Nipple BSP vs NPT: Uses & Sizing for Dubai Projects – Understand the difference between BSP and NPT threads and how to choose the right type for your Dubai projects.

- Supply Chain Management vs Logistics – Learn the key differences between supply chain management and logistics in modern industrial operations.