The oil and gas industry needs many specialized components and equipment. Making these things requires advanced fabrication skills.

Many oil companies choose to transfer these oilfield fabrication services to third-party providers.

This allows them to focus on their core operations while getting high-quality fabricated products. Outsourcing fabrication can provide several key benefits.

This blog post will explain the top advantages of using external oilfield fabrication services for your needs.

Cost Savings

One of the biggest benefits is cost savings. Setting up an in-house fabrication facility is extremely expensive. You need specialized machinery, tools, raw materials inventory, and a skilled workforce.

Outsourcing oilfield fabrication services eliminates these substantial capital and operating costs. Reputed fabrication companies can use their scale and bulk purchasing power.

This allows them to get materials at lower rates and pass on those savings. Their specialized expertise also leads to efficient processes and less material waste.

Access to Expertise

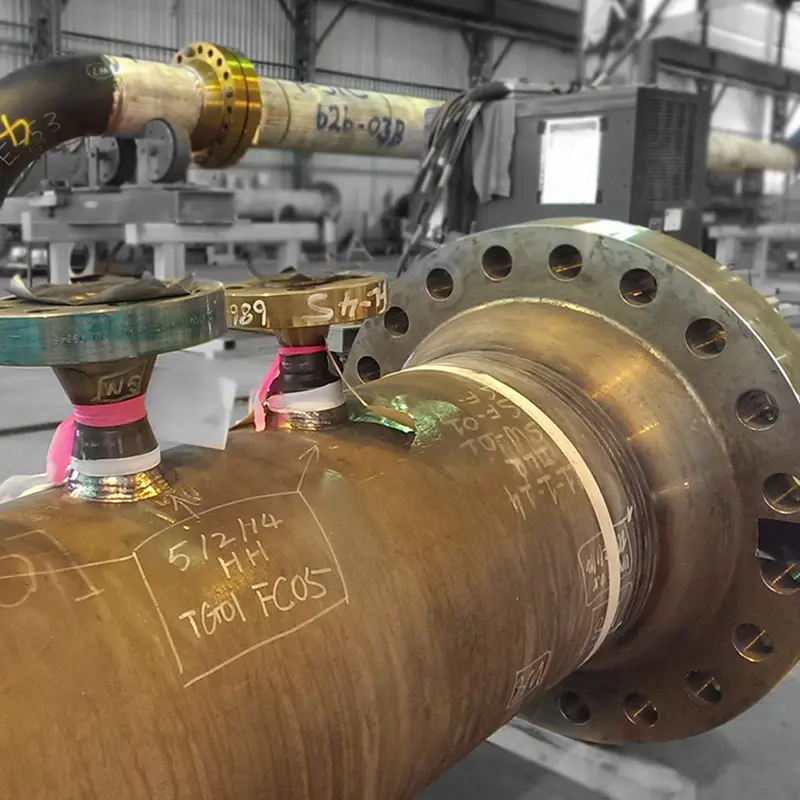

Services related to oilfield fabrication necessitate highly specialized technical expertise. Acquiring and educating the appropriate personnel internally can be difficult and time-consuming.

One benefit of outsourcing is that it gives you instant access to a pool of highly qualified fabricators and engineers. These businesses keep up with the most recent standards, codes, and best practices in the industry.

They use modern techniques, equipment, and technologies designed for oilfield applications. Their specialized know-how ensures every component meets precise specifications reliably.

Flexibility and Scalability

Your fabrication needs can fluctuate considerably based on project cycles and market conditions. An in-house setup requires maintaining excess capacity to handle peaks inefficiently.

Outsourcing partners offer flexibility to increase production up or down swiftly based on your specific requirements. You only pay for the capacity you currently need without paying for wasteful expenses.

This scalability allows you to take on more projects. You can meet tight deadlines by using oilfield fabrication services instead of being limited by your own constraints.

Quality and Compliance

In the oilfield business, even the smallest defect can have serious consequences in terms of safety, environmental impact, and operational downtime. Oilfield fabrication services have strong quality control processes to ensure zero defects.

They follow stringent testing, inspection, and documentation protocols. All components are built to comply with relevant industry specifications. This quality focus minimizes rework and errors.

Faster Turnaround

Since fabrication is their core competency, outsourced partners can streamline workflows for maximum efficiency. Their specialized facilities are set up specifically for high-volume repetitive fabrication work.

They can easily handle urgent requests by allocating more resources from their larger workforce and multiple production bays. This allows a much faster turnaround than what’s possible in-house.

Focus on Core Business

Outsourcing oilfield fabrication lets you focus entirely on your core oil and gas activities instead of getting sidetracked by non-core functions. This leads to higher productivity and efficiency in your primary operations.

Conclusion

Opting for specialized oilfield fabrication services provides immense value through cost optimization, access to skilled expertise, flexibility, and scalability, stringent quality, faster turnarounds, and the ability to concentrate on your core business.