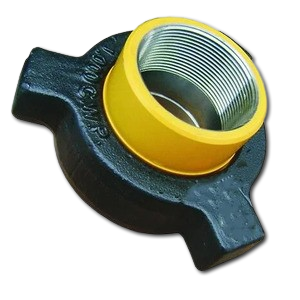

HAMMER UNION FIG 50

1. Description:

- Product Name: Hammer Union Figure 50

- Type: High-pressure connection fitting

- Material: Usually carbon steel, stainless steel, or other alloy steels depending on application.

- Use: Designed for high-pressure fluid and gas applications, commonly used in oil and gas industries, well services, and pipeline systems.

- Design: Comprised of two or more components that are tightened together using a threaded connection with an additional nut, making it easier to assemble and disassemble for maintenance.

- Color Code: Typically color-coded for ease of identification (e.g., red, blue, or yellow).

2. Specifications:

- Pressure Class:

- Typically, Hammer Union Figure 50 is rated for up to 5,000 PSI (pounds per square inch).

- Pressure classes may vary based on material and design, with common classifications being 3,000 PSI, 5,000 PSI, or 10,000 PSI.

- Size Range:

- From 1″ to 4″ (diameter sizes).

- Larger sizes (above 4″) can be custom-made depending on application.

- End Connections:

- Threaded, Flanged, or Butt Weld depending on the design.

- Material Types:

- Carbon Steel (A105) for general applications.

- Stainless Steel (316) for higher corrosion resistance.

- Alloy Steel or Nickel Alloys for high-temperature or high-pressure services.

- Temperature Range:

- Typically -50°F to 300°F (-45°C to 150°C) for standard materials.

- Can vary with specific materials used for extreme temperature conditions.

- Thread Type:

- API or BS threads, depending on industry standards.

- Seal Type:

- O-ring seals (usually nitrile rubber, or fluorocarbon, depending on application).

3. Classification:

- API Classification:

- Hammer Union Figure 50 fittings are often built to API 16C standards for high-pressure connections in drilling and well services.

- End Connections:

- Compatible with BSPT (British Standard Pipe Tapered) threads or NPT (National Pipe Thread) threads, among other end types.

- Material Grade:

- Classified based on material composition (e.g., ASTM A105, A350 LF2 for carbon steel; ASTM A182 for stainless steel).

4. Applications:

- Oil & Gas: Used in drilling, well testing, and pressure testing.

- Water Systems: For high-pressure water transfer in industrial settings.

- Chemical Processing: Handling corrosive chemicals at high pressure.

- Industrial Systems: For high-pressure steam and fluid transport.

5. Additional Features:

- Easy Assembly/Disassembly: The hammer union’s design makes it easier to connect and disconnect parts under high pressure, minimizing downtime.

- Leak Prevention: Seals are designed to prevent fluid or gas leakage even at high pressure.

6. Standards:

- API 6A: For wellhead equipment.

- ASME B16.5: For flanges.

- ANSI B16.5: Flanged fittings.

- ISO 9001: Quality management system.

7. Advantages:

- Reliability: High-quality material ensures strong and reliable connections.

- Quick and Safe Connections: Designed for ease of use in high-pressure applications, which saves time during maintenance and ensures safety.

- Durability: Hammer unions are known for their durability in harsh conditions (extreme pressures, temperatures, and chemicals).