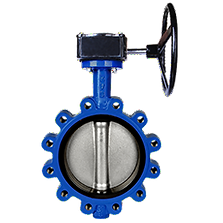

CAST IRON LUGGED TYPE BUTTERFLY VALVE LEVER OPERATED

- Product Name: Cast Iron Lug Type Butterfly Valve, Lever Operated

- Material:

- Body: Cast Iron (ASTM A126 Class B or equivalent)

- Disc: Ductile Iron (ASTM A536 Grade 65-45-12) or Cast Iron

- Stem: Stainless Steel (ASTM A276 Type 304 or equivalent)

- Seat: EPDM (Ethylene Propylene Diene Monomer), NBR (Nitrile Butadiene Rubber), or other suitable elastomer

- Lever: Ductile Iron or Stainless Steel

- Connection Type: Lug style with flanged ends for easy installation between flanges of compatible piping systems.

- Design:

- Butterfly valve design with a disc-shaped closing mechanism (disc) mounted on a rotating shaft (stem).

- Lever-operated mechanism for manual actuation, providing quick and easy operation to open or close the valve.

- Lug style body design with threaded bolt holes allows for installation between flanges using bolts and nuts, providing a secure and leak-tight connection.

- Size Range:

- Available in various sizes ranging from 2 inches to 24 inches or larger, depending on the manufacturer and application requirements.

- Pressure Rating:

- Rated for various pressure ratings depending on the size, material, and application, typically up to ANSI Class 150 or higher.

- Temperature Rating:

- Suitable for a wide range of temperatures, typically from -20°C to 120°C (-4°F to 248°F), depending on the elastomer seat material and application.

- Features:

- Corrosion Resistance: Cast iron construction provides good resistance to corrosion, suitable for use in water, air, and non-corrosive fluid applications.

- Bubble-Tight Seal: Elastomer seat provides a tight seal against the disc, ensuring leak-free operation even at low pressures.

- Lever Operation: Lever handle provides manual actuation for opening and closing the valve, allowing for quick adjustment of flow rates.

- Lug Style: Lug design allows for easy installation and removal of the valve from the pipeline without disturbing the flange connections.

- Versatility: Suitable for a wide range of applications, including HVAC systems, water distribution, irrigation, and general industrial applications.

- Application:

- Ideal for use in HVAC systems, water distribution networks, industrial process piping, and other applications where reliable flow control is required.

- Commonly used in industries such as water treatment plants, chemical processing, power generation, and wastewater treatment.

- Standards Compliance:

- Manufactured to meet or exceed relevant industry standards and specifications, such as API 609, MSS SP-67, AWWA C504, and others, ensuring quality, reliability, and safety.