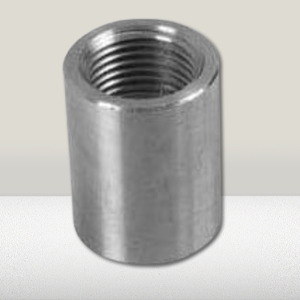

BOTHWELL® TAIWAN THREADED FULL SOCKET COUPLING FORGED STEEL

Bothwell Taiwan manufactures high-quality pipe fittings, including full socket couplings designed to handle high-pressure applications. These couplings are used to connect two pieces of pipe securely and are rated for pressures of 3000 psi and 2000 psi, making them suitable for various industrial uses.

Specification

- Material Composition:

- Made from high-strength materials to ensure durability and corrosion resistance.

- Common materials include:

- Carbon Steel: ASTM A105

- Stainless Steel: ASTM A182 F304, F316

- Alloy Steel: ASTM A182 F11, F22

- Low-Temperature Carbon Steel: ASTM A350 LF2

- Pressure Rating:

- 3000 psi (210 bar)

- 2000 psi (140 bar)

- Size Range:

- Available in various sizes to accommodate different pipe diameters, typically ranging from 1/8 inch to 4 inches.

- Standards and Certifications:

- Manufactured in compliance with international standards such as ASME B16.11 and ASTM standards.

- Certificates of compliance and material test reports are usually provided.

Classification

- By Material:

- Carbon Steel: ASTM A105

- Stainless Steel: ASTM A182 F304, F316

- Alloy Steel: ASTM A182 F11, F22

- Low-Temperature Carbon Steel: ASTM A350 LF2

- By Size:

- Small Diameter: 1/8 inch to 1 inch

- Medium Diameter: 1-1/4 inch to 2 inches

- Large Diameter: 2-1/4 inch to 4 inches

- By Pressure Rating:

- 3000 psi

- 2000 psi

- By Connection Type:

- Socket Weld: For a permanent and leak-proof connection.

Description

- Applications:

- Oil and Gas Industry: Used to connect pipes in high-pressure environments, such as drilling rigs and pipelines.

- Petrochemical Plants: Essential for joining process lines where high-pressure containment is required.

- Power Plants: Utilized in high-pressure steam and water lines to ensure system integrity.

- General Industrial Use: Suitable for various high-pressure fluid handling systems.

- Advantages:

- High Pressure Handling: Designed to withstand pressures up to 3000 psi or 2000 psi, making them suitable for demanding applications.

- Durable Construction: Made from high-strength materials, ensuring long service life and reliability.

- Secure Connection: Socket weld design provides a permanent and leak-proof connection.

- Compliance with Standards: Meets international standards for safety and performance.

- Limitations:

- Installation Expertise Required: Proper installation requires skilled personnel to ensure a leak-proof and secure connection.

- Material Cost: Higher-grade materials like stainless steel and alloy steel can be more expensive compared to carbon steel.

- Maintenance and Care:

- Regular Inspection: Periodically check for signs of wear, corrosion, or damage to prevent leaks and ensure safety.

- Proper Installation: Ensure couplings are installed correctly according to manufacturer guidelines and industry standards.

- Clean and Dry Storage: Store fittings in a clean, dry environment to prevent contamination and corrosion before use.