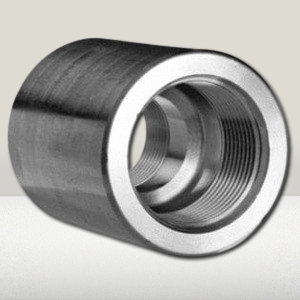

BOTHWELL® TAIWAN SWEDGE NIPPLE IN FORGED STEEL DUBAI

Bothwell Taiwan produces durable swedge nipples designed for high-pressure applications. Swedge nipples are used to connect pipes or fittings of different sizes and are typically threaded at both ends.

Specification

- Material Composition:

- Constructed from high-quality, corrosion-resistant materials for long-lasting performance.

- Common materials include:

- Carbon Steel: ASTM A105

- Stainless Steel: ASTM A182 F304, F316

- Alloy Steel: ASTM A182 F11, F22

- Low-Temperature Carbon Steel: ASTM A350 LF2

- Pressure Rating:

- 3000 psi (210 bar)

- 2000 psi (140 bar)

- Size Range:

- Available in various sizes, typically from 1/8 inch to 4 inches, to accommodate different pipe sizes and pressure requirements.

- Standards and Certifications:

- Manufactured in compliance with ASME B16.11 and ASTM standards.

- Certificates of compliance and material test reports are usually provided.

Classification

- By Material:

- Carbon Steel: ASTM A105

- Stainless Steel: ASTM A182 F304, F316

- Alloy Steel: ASTM A182 F11, F22

- Low-Temperature Carbon Steel: ASTM A350 LF2

- By Size:

- Small Diameter: 1/8 inch to 1 inch

- Medium Diameter: 1-1/4 inch to 2 inches

- Large Diameter: 2-1/4 inch to 4 inches

- By Pressure Rating:

- 3000 psi

- 2000 psi

- By Connection Type:

- Threaded Ends: NPT or BSPT threads are common for secure connections.

Description

- Applications:

- Oil and Gas Industry: Used to connect pipes of different sizes in high-pressure environments, such as wellheads and pipelines.

- Petrochemical Plants: Essential for connecting process lines with different diameters while maintaining high-pressure containment.

- Power Plants: Used in high-pressure steam and water lines to ensure efficient system operation.

- General Industrial Use: Suitable for various high-pressure fluid handling systems.

- Advantages:

- High Pressure Handling: Capable of withstanding pressures up to 3000 psi or 2000 psi, making them suitable for demanding industrial applications.

- Durable Construction: Made from robust materials to ensure longevity and reliability.

- Versatile Sizing: Available in multiple sizes to accommodate different pipe diameters and pressure requirements.

- Compliance with Standards: Meets international standards, ensuring safety and performance.

- Limitations:

- Material Cost: Higher-grade materials like stainless steel and alloy steel can be more expensive compared to carbon steel.

- Installation Expertise: Proper installation requires skilled personnel to ensure a leak-proof and secure connection.

- Maintenance and Care:

- Regular Inspection: Periodically inspect for signs of wear, corrosion, or damage to ensure system integrity.

- Proper Installation: Ensure swedge nipples are installed according to manufacturer guidelines and industry standards.

- Clean and Dry Storage: Store fittings in a clean, dry environment to prevent contamination and corrosion before use.