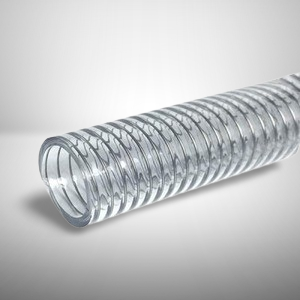

PVC HEAT RESISTANT STEEL WIRE HOSE

High Temperature Resistant Steel Wire Hoses are engineered to withstand high temperatures while maintaining flexibility, durability, and strength. These hoses are essential for applications involving the transfer of hot fluids, gases, and steam in industrial environments.

Specification

- Material:

- Hose: Typically made from heat-resistant synthetic rubber, silicone, or thermoplastic.

- Reinforcement: Embedded high-tensile steel wire helix.

- Properties:

- Inner Diameter: Typically ranges from 12 mm to 200 mm.

- Wall Thickness: Varies based on the inner diameter and specific application requirements.

- Pressure Rating: High pressure capabilities, typically ranging from 10 bar to 30 bar or more, depending on the hose size and construction.

- Temperature Range: -40°C to +260°C (-40°F to 500°F), depending on the hose material and construction.

- Bend Radius: Depending on hose size and material, designed to be flexible and maintain integrity under bending.

- Length:

- Standard lengths are typically 30 meters or 50 meters per roll, but can be customized as per requirements.

- Color:

- Generally available in colors like black, red, or custom colors upon request.

- Finish:

- Smooth or slightly corrugated outer surface to enhance flexibility and durability.

Classification

- By Diameter:

- Small Diameter: 12 mm to 25 mm.

- Medium Diameter: 26 mm to 100 mm.

- Large Diameter: 101 mm to 200 mm.

- By Application:

- Industrial Applications: For high-temperature fluid transfer.

- Steam and Hot Water: Suitable for steam cleaning, hot water transfer, and steam lines.

- Chemical Transport: Designed to handle high-temperature chemicals.

- Exhaust Systems: Used in high-temperature exhaust and ventilation systems.

- Automotive and Aerospace: Suitable for high-temperature applications in automotive and aerospace industries.

Description

- Applications:

- Steam Transfer: Ideal for transferring steam in industrial cleaning and processing applications.

- Hot Water and Fluids: Used for transferring hot water and other high-temperature fluids.

- Chemical Handling: Suitable for handling high-temperature chemicals and aggressive liquids.

- Exhaust and Ventilation: Commonly used in high-temperature exhaust and ventilation systems.

- Automotive and Aerospace: Used in high-temperature applications within the automotive and aerospace industries, such as coolant and turbocharger systems.

- Advantages:

- High Temperature Resistance: Capable of withstanding extremely high temperatures, making it suitable for demanding applications.

- Durability: The embedded steel wire provides strength and prevents kinking or collapsing under pressure and high temperatures.

- Flexibility: Despite its strength, the hose remains flexible, allowing for easy handling and installation.

- Chemical Resistance: Excellent resistance to a wide range of chemicals, oils, and greases, depending on the specific material of the hose.

- Abrasion Resistance: Resistant to abrasion, extending the life of the hose in harsh conditions.

- Corrosion Resistance: Resistant to corrosion from water, steam, and other substances, enhancing longevity.

- Limitations:

- Weight: Heavier than standard hoses due to the steel wire reinforcement and specialized materials.

- Cost: More expensive than standard PVC or rubber hoses due to its enhanced construction and materials.

- Handling: Requires careful handling to avoid damage to the steel wire reinforcement.

- Maintenance and Care:

- Regularly inspect for signs of wear, abrasion, or damage, especially in high-temperature environments.

- Clean with water and mild detergent; avoid using harsh chemicals that could degrade the hose material.

- Store in a cool, dry place away from direct sunlight and harsh environmental conditions to extend the life of the hose.

- Ensure proper handling to avoid kinking or excessive bending, which can compromise the hose’s structural integrity.