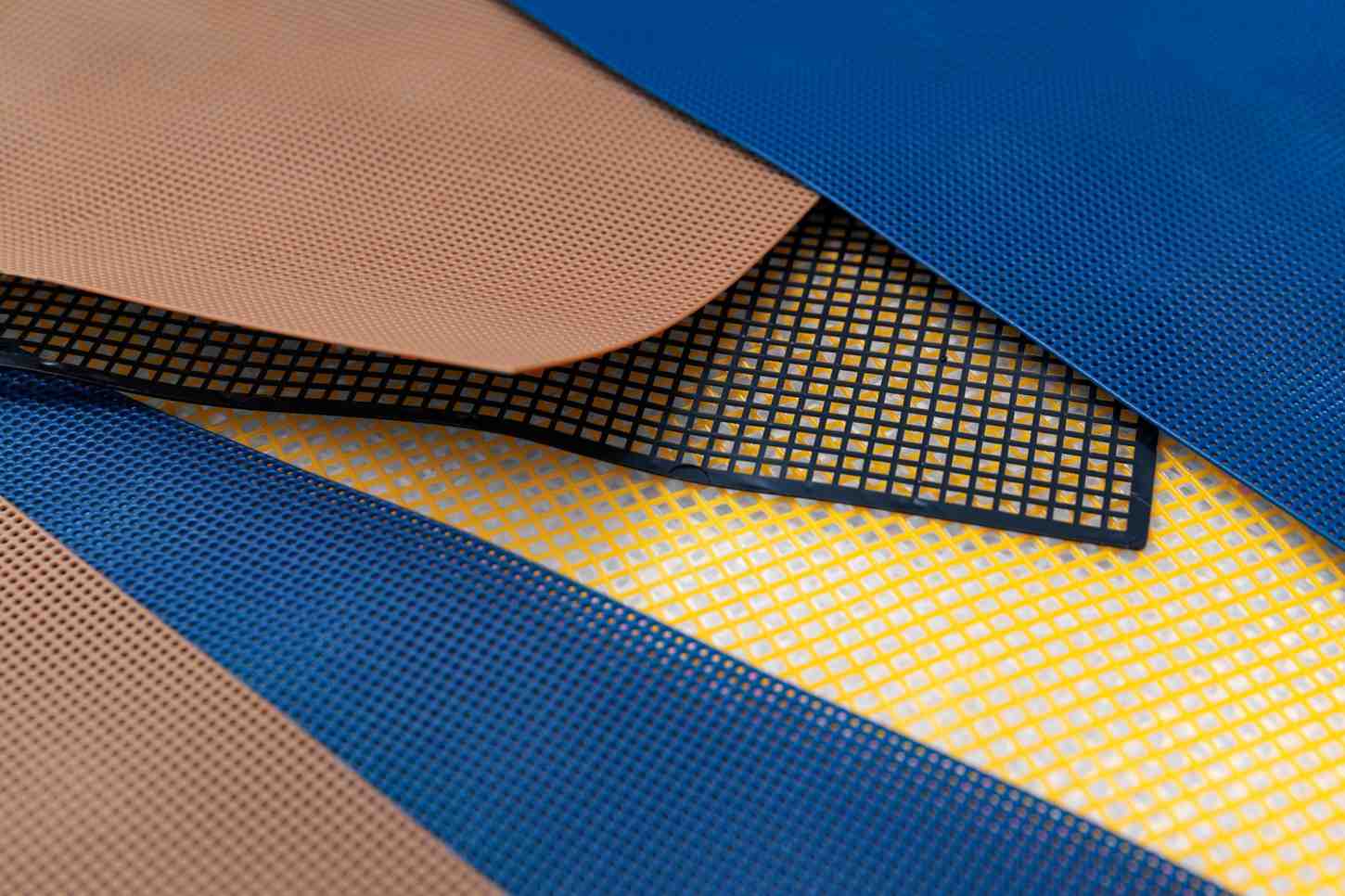

Rubber sheets are essential materials widely used in industries due to their durability, flexibility, and resistance to environmental and chemical factors. Selecting the right type of rubber sheet is crucial for ensuring optimal performance, safety, and longevity in applications ranging from automotive and construction to food, medical, and industrial sectors.

Understanding the properties, advantages, and applications of different rubber sheets can help professionals and businesses make informed decisions.

In this comprehensive guide, we will explore the various types of rubber sheets, their unique properties, and their practical uses across industries.

1. Natural Rubber Sheets (NR)

Natural rubber sheets are derived from latex extracted from rubber trees. They are highly elastic, tear-resistant, and flexible at low temperatures.

Their resilience allows them to return to their original shape after stretching or compression, making them ideal for shock absorption, vibration dampening, and protective applications.

Key properties of natural rubber sheets:

- High tensile strength and elasticity

- Excellent abrasion and wear resistance

- Tear resistance and flexibility

Common uses:

- Shock mounts and anti-vibration pads

- Seals, gaskets, and hoses

- Conveyor belts and protective coatings

Natural rubber sheets, also known as NR sheets, are widely used in industrial and automotive applications where vibration control and mechanical resilience are required.

2. Neoprene Rubber Sheets (CR)

Neoprene rubber sheets, also called chloroprene rubber, are synthetic sheets prized for chemical resistance, weather durability, and flame resistance.

Neoprene sheets maintain their physical properties over a wide temperature range, making them suitable for both indoor and outdoor applications.

Key properties of neoprene rubber sheets:

- Excellent resistance to oils, chemicals, and UV rays

- High durability and elasticity

- Weathering and aging resistance

Common uses:

- Industrial gaskets and seals

- Hoses and protective coverings

- Marine applications like wetsuits and boat fenders

Neoprene rubber sheets or CR sheets are a popular choice in chemical-exposed environments and for applications where long-lasting durability is critical.

3. Nitrile Rubber Sheets (NBR)

Nitrile rubber sheets are recognized for their exceptional resistance to petroleum, oils, and fuels. They provide mechanical strength and remain flexible in low-temperature environments, making them suitable for oil-rich and automotive industries.

Key properties of NBR sheets:

- Oil, fuel, and chemical resistance

- High tensile strength and durability

- Flexible and resilient

Common uses:

- Fuel system components

- Oil seals and gaskets

- Conveyor belts in oil and gas industries

NBR sheets or nitrile rubber sheets are also used in food processing and electrical applications where exposure to oils and solvents is common.

4. EPDM Rubber Sheets

EPDM rubber sheets are known for outstanding resistance to weather, UV, ozone, and aging. Their durability and flexibility make them perfect for outdoor applications, water sealing, and electrical insulation.

EPDM (Ethylene Propylene Diene Monomer) is highly resistant to acids, alkalis, and ketones, making it versatile for industrial and environmental applications.

Key properties of EPDM sheets:

- Excellent weather, ozone, and UV resistance

- Flexibility over a wide temperature range

- Chemical resistance

Common uses:

- Roofing membranes and outdoor seals

- Electrical insulation and cable jointing

- Automotive weatherstripping and gaskets

EPDM rubber sheets are ideal for outdoor or exposed conditions where weather-resistant rubber sheets are needed for long-term performance.

5. Silicone Rubber Sheets (VMQ)

Silicone rubber sheets are highly versatile, offering heat resistance, flexibility, and FDA compliance for food and medical applications. They maintain stability over extreme temperatures and are resistant to UV, ozone, and many chemicals.

Key properties of silicone sheets:

- High-temperature resistance (-60°C to 230°C)

- Flexible and resilient

- Food-grade and FDA-approved

Common uses:

- Seals and gaskets in food and medical industries

- High-temperature applications

- Electrical insulation and protective layers

Silicone sheets, also known as VMQ sheets, are essential for industries requiring FDA-approved rubber sheets for safety and regulatory compliance.

6. Viton Fluoroelastomer Rubber Sheets (FKM)

Viton rubber sheets, or fluoroelastomers (FKM), are premium materials designed for high-performance industrial applications. They offer unmatched heat, chemical, and solvent resistance, making them ideal for extreme environments.

Key properties of Viton sheets:

- Exceptional heat and chemical resistance

- Excellent thermal stability

- Suitable for high-pressure and high-temperature conditions

Common uses:

- Aerospace and automotive seals

- Chemical-resistant gaskets

- Industrial applications with aggressive chemicals

Viton rubber sheets or FKM sheets provide high-performance solutions where durability and chemical resistance are critical, outperforming conventional rubber in demanding industrial applications.

7. Specialty Rubber Sheets

Specialty rubbers are engineered to meet specific industrial needs. These include SBR (Styrene-Butadiene Rubber) for abrasion resistance, Butyl rubber (IIR) for airtight applications, PU (Polyurethane) sheets for high load-bearing, and Hypalon (CSM) for chemical and UV resistance.

Uses:

- Tires, rollers, and industrial parts

- Inflatable structures and pond liners

- Seals and gaskets for harsh industrial conditions

Specialty rubber sheets, including SBR, PU, and CSM rubber sheets, offer tailored solutions for industries requiring abrasion-resistant, airtight, or chemical-resistant materials.

Factors to Consider When Choosing a Rubber Sheet

When selecting the right rubber sheet, consider:

- Application environment: Indoor, outdoor, chemical exposure, temperature extremes

- Mechanical properties: Tensile strength, flexibility, abrasion resistance

- Compliance: Food-grade, FDA-approved, industrial standards

- Thickness and dimensions: Ensure compatibility with equipment and machinery

Choosing the correct material ensures durability, safety, and cost-effectiveness in industrial applications.

AI Overview

Rubber sheets are versatile industrial materials used for sealing, insulation, and protection. This guide explains different rubber sheet types, properties, and uses across industries.

FAQs

What are rubber sheets commonly used for in industries?

Rubber sheets are used for sealing, insulation, vibration control, and surface protection in automotive, construction, electrical, food, and industrial applications.

Which rubber sheet is best for oil and fuel resistance?

Nitrile rubber sheets are best suited for oil and fuel resistance, making them ideal for automotive components, gaskets, and oil handling systems.

What type of rubber sheet is suitable for outdoor applications?

EPDM rubber sheets are ideal for outdoor use due to their strong resistance to weather, UV exposure, ozone, and environmental aging.

Are silicone rubber sheets safe for food and medical use?

Yes, silicone rubber sheets are food-grade and FDA-approved, making them suitable for food processing, medical devices, and high-temperature environments.

When should Viton rubber sheets be used?

Viton rubber sheets are used in high-performance industrial applications that involve extreme heat, aggressive chemicals, and high-pressure conditions.

Conclusion

Choosing the right type of rubber sheet is critical for industrial, automotive, food, medical, and construction applications. From natural rubber sheets with excellent elasticity to Viton and silicone sheets designed for extreme chemical and heat resistance, each type provides unique advantages. Incorporating NBR, EPDM, SBR, and specialty rubbers ensures performance tailored to specific operational needs.

If you need reliable and durable rubber sheets for industrial, commercial, or specialized applications, Mustafa Ashqar Trading LLC supplies a wide range of rubber sheets along with all types of pipe fittings.

Get in touch today to discuss your requirements and order quality products you can trust for long-term performance.

Read More Experts Insights

Explore expert articles on pipe fittings, valves, and industrial materials to help you choose the right solutions for your next project in UAE.

- Common Pipe Fitting Failures: Causes & Prevention Tips – Learn about frequent pipe fitting failures and how to prevent them with proper materials and maintenance.

- Different Types of Flanges and Their Uses – practical guide to flange types, functions, and industrial applications.

- Why High‑Zinc GI Pipes Are Trending in UAE Construction – High‑Zinc GI Pipes: The Trending Choice in UAE Construction.

- Understanding Lüdecke Couplings and Their Uses – Enhance Pipe Strength, Durability, and Cost-Efficiency in Construction.

- Top Signs Your Hose Needs Replacement – Key warning signs to prevent leaks, failures, and costly downtime.