Selecting appropriate components for industrial piping systems requires careful consideration and technical knowledge. Among the essential fittings used in piping networks, pipe reducers play a crucial role in connecting pipes of different diameters, maintaining flow efficiency, and ensuring system integrity. For professionals working on piping projects in the UAE, understanding how to select the correct pipe reducers can save time, money, and prevent potential system failures.

Understanding Pipe Reducer Fundamentals

It serve as transition pieces between pipes of different sizes. They create a smooth path for fluids or gases to flow from a larger diameter pipe to a smaller one without causing excessive turbulence or pressure drop. Available in two main configurations—concentric and eccentric—each type serves specific purposes in piping design.

Concentric pipe reducers feature a symmetrical design where the centerlines of both the larger and smaller pipes align perfectly. Eccentric variants, meanwhile, have one flat side with offset centerlines, making them ideal for installations where air pocket prevention or complete drainage is necessary.

Material Considerations for UAE Conditions

The harsh climate and specific industrial requirements in the UAE demand careful material selection for pipe reducers. High temperatures, humidity, and sometimes corrosive substances require materials that can withstand challenging conditions.

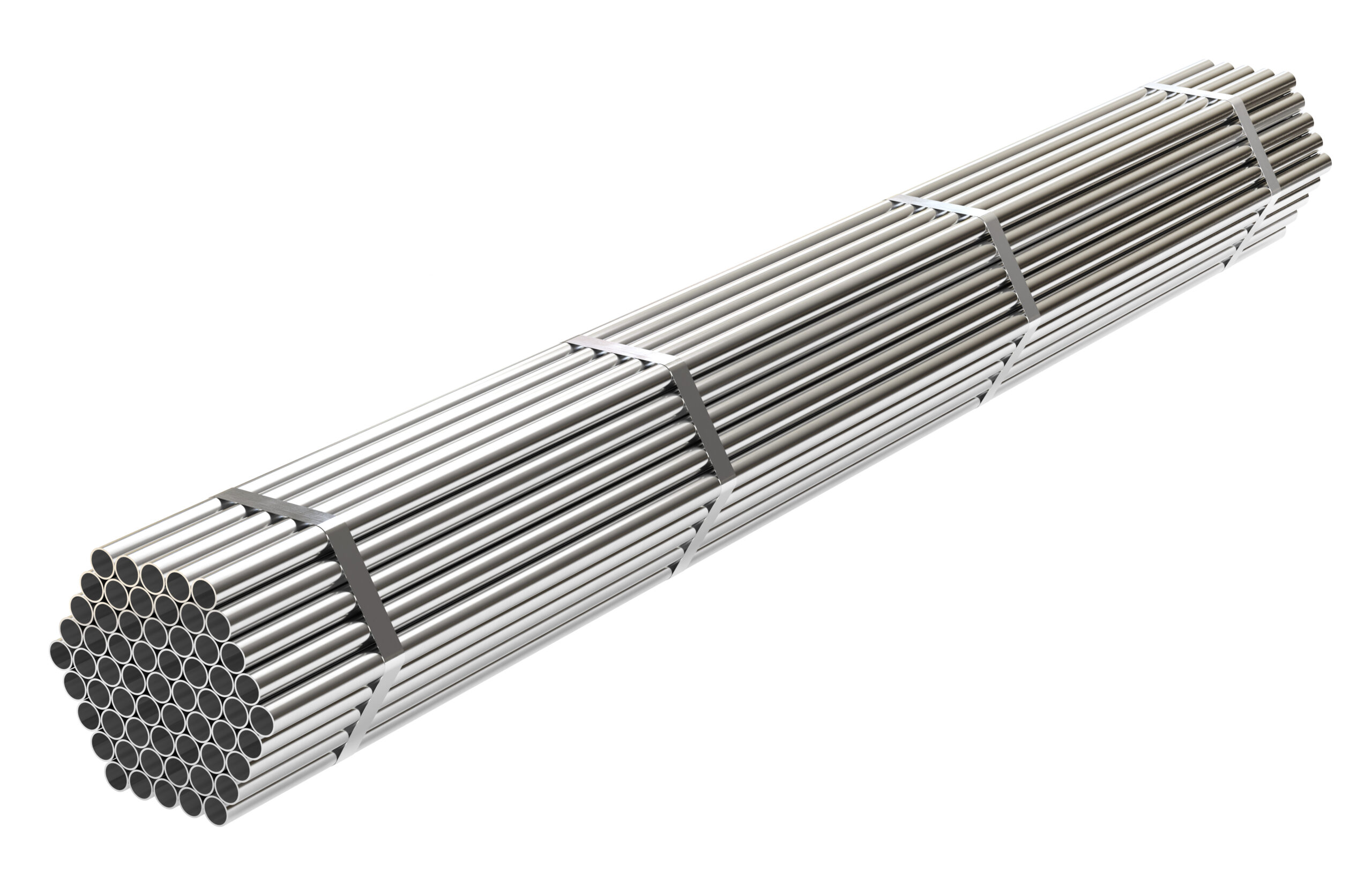

Stainless steel pipe reducers offer excellent corrosion resistance and work well in applications involving potable water, food processing, and chemical transfer systems. Carbon steel variants provide strength and durability for general industrial applications, making them popular choices for oil and gas operations abundant in the region.

Size and Schedule Compatibility

Accurate sizing represents perhaps the most critical aspect of selecting pipe reducers. Engineers must consider both the inlet and outlet diameters to ensure proper connections. Equally important is matching the pipe schedule (wall thickness) of connected pipes to maintain system integrity.

When specifying pipe reducers, always note both end sizes clearly (for example, a 3″ × 2″ reducer connects a 3-inch pipe to a 2-inch pipe). Additionally, understanding the schedule (such as Schedule 40 or Schedule 80) ensures compatible wall thickness throughout your piping system.

Connection Types and Installation Requirements

It comes with various end connections suitable for different installation methods. Welded connections offer permanent, leak-proof joints ideal for high-pressure systems common in industrial facilities across the UAE. Threaded connections allow for easier maintenance access but may require additional sealing measures in high-pressure applications.

Flanged pipe reducers facilitate simple assembly and disassembly, making them popular choices for systems requiring regular maintenance. Socket weld connections combine ease of installation with excellent joint strength for smaller diameter pipes.

Flow Dynamics and Pressure Considerations

Flow characteristics change when fluid moves through pipe reducers, potentially creating pressure drops or turbulence. For optimal system performance, engineers should calculate these effects during the design phase.

Gradual pipe reducers with lower reduction ratios minimize turbulence and pressure loss. When significant size reduction is unavoidable, consider using multiple reducers in sequence rather than one with a dramatic diameter change.

Conclusion

Selecting appropriate pipe reducers requires balancing technical requirements, material properties, and installation practicalities. For projects in the UAE’s demanding environment, taking time to properly specify these components pays dividends through improved system performance and reduced maintenance needs.