When it comes to industrial, commercial, or residential piping systems, choosing the right pipe fittings is crucial for long-term durability, safety, and cost-effectiveness. Two of the most commonly used materials are galvanized steel and stainless steel. Both offer distinct advantages and limitations depending on the application.

In this comprehensive guide, we will explore the differences, uses, benefits, and considerations of galvanized vs stainless steel pipe fittings to help you make an informed decision.

Understanding Galvanized Pipe Fittings

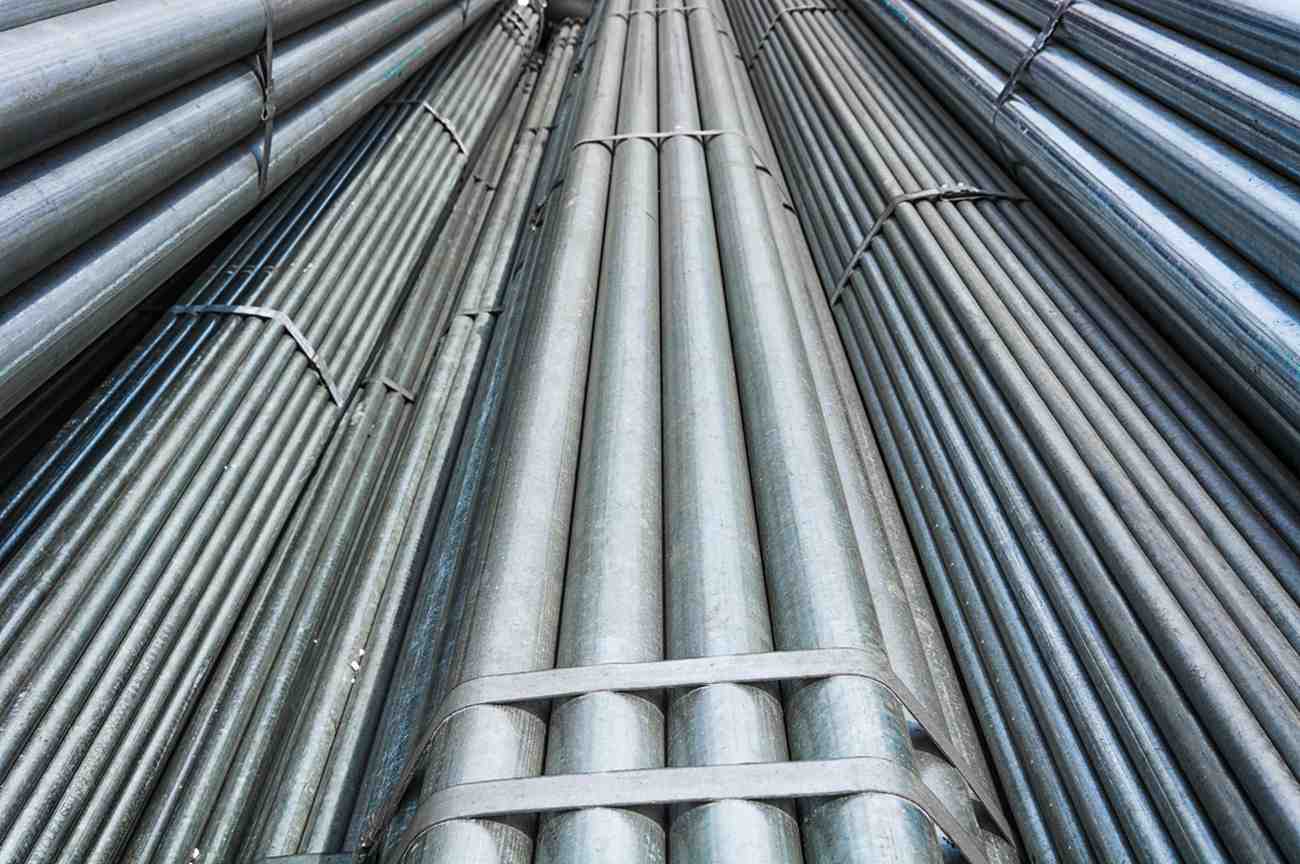

Galvanized steel pipe fittings are made by coating regular steel with a layer of zinc to prevent corrosion. This protective layer makes galvanized fittings a popular choice for water supply, HVAC systems, and industrial piping where moderate resistance to rust is needed.

Advantages of Galvanized Fittings

- Cost-effective: Galvanized fittings are generally cheaper than stainless steel options, making them ideal for large-scale plumbing projects or construction works where budget is a key factor.

- Corrosion resistance: The zinc coating protects the steel from rust and oxidation, which can extend the life of the piping system under normal conditions.

- Durability: Galvanized steel is strong and can handle high pressure, making it suitable for water pipelines, fire sprinkler systems, and outdoor installations.

Limitations of Galvanized Fittings

- Limited lifespan in extreme conditions: Over time, the zinc layer can wear off, exposing the steel to corrosion, especially in areas with high humidity or acidic water.

- Not ideal for chemical applications: Galvanized fittings may react with certain chemicals, making them unsuitable for food processing or industrial chemical lines.

Understanding Stainless Steel Pipe Fittings

Stainless steel pipe fittings are made from alloys containing chromium, which provides superior corrosion resistance compared to galvanized steel. Stainless steel is widely used in environments that require high hygiene standards, durability, and resistance to harsh conditions.

Advantages of Stainless Steel Fittings

- Exceptional corrosion resistance: Stainless steel fittings can withstand water, chemicals, and environmental factors that would typically corrode galvanized fittings.

- Longevity: These fittings have a longer service life, which makes them cost-effective over the long term despite a higher initial investment.

- Versatility: Stainless steel fittings are ideal for chemical, food-grade, marine, and industrial applications due to their non-reactive properties.

- Low maintenance: Stainless steel does not require regular painting or coating, reducing ongoing maintenance costs.

Limitations of Stainless Steel Fittings

- Higher cost: The upfront cost of stainless steel fittings is higher compared to galvanized steel.

- Specialized installation: Stainless steel may require specific tools and expertise for welding or joining, increasing installation complexity.

Key Differences Between Galvanized and SS Pipe Fittings

To make the comparison easier, let’s break down the key differences between galvanized and stainless steel pipe fittings based on important factors.

| Property | Galvanized Pipe Fittings | Stainless Steel Pipe Fittings |

|---|---|---|

| Cost | Lower | Higher |

| Corrosion Resistance | Moderate | Very High |

| Typical Use | Water pipelines, HVAC, fire sprinkler | Chemical processing, food-grade, marine, industrial |

| Maintenance | Low to moderate | Very low |

| Durability | Strong, but zinc layer can wear off | Extremely durable and long-lasting |

| Installation | Easy, standard tools | Requires specialized tools and expertise |

This table highlights that stainless steel fittings are the better choice for environments demanding high corrosion resistance and hygiene, whereas galvanized fittings offer a cost-effective solution for standard water and industrial pipelines.

Applications of Galvanized and Stainless Steel Fittings

Galvanized Pipe Fittings Applications

- Water Supply Systems: Galvanized pipes are commonly used in residential and commercial water distribution due to their corrosion protection.

- Fire Sprinkler Systems: The strength and moderate rust resistance make them suitable for fire suppression systems.

- HVAC Systems: Air conditioning and heating ducts often use galvanized fittings to resist moisture and temperature changes.

Stainless Steel Pipe Fittings Applications

- Chemical and Industrial Plants: Stainless steel handles harsh chemicals and extreme temperatures better than galvanized steel.

- Food and Beverage Industry: Stainless steel is safe for food and drink applications due to its non-reactive properties.

- Marine Environments: Saltwater exposure can quickly corrode galvanized fittings, making stainless steel ideal for ships, docks, and offshore installations.

Choosing the Right Fitting Material

When deciding between galvanized vs stainless steel pipe fittings, consider the following factors:

- Budget: If the project has strict budget limits, galvanized steel provides a cost-effective solution.

- Environmental Conditions: For high-humidity, coastal, or chemical environments, stainless steel is preferable.

- Longevity Requirements: Stainless steel lasts longer and reduces long-term replacement and maintenance costs.

- Industry Standards: Certain industries, such as food processing or pharmaceuticals, mandate stainless steel for safety and compliance.

- Pressure and Load: Both materials can handle high-pressure applications, but stainless steel performs better under extreme conditions.

Insights for Industrial Buyers

For businesses, contractors, and industrial buyers, knowing the differences can improve procurement decisions. High-quality stainless steel fittings may involve higher initial costs but significantly reduce downtime, maintenance, and replacement expenses.

Conversely, galvanized pipe fittings remain a strong option for residential, commercial, and light industrial use where budget and standard durability are sufficient.

Additionally, understanding regional water quality, environmental conditions, and the chemical compatibility of your pipelines can make a huge difference in the lifespan of your piping system.

AI Overview

Compare galvanized vs stainless steel pipe fittings, their durability, corrosion resistance, applications, and choose the right fittings for cost-effective, long-lasting piping solutions.

FAQs

Which one is stronger, galvanized or stainless steel?

Stainless steel is stronger than galvanized steel at similar thicknesses due to higher tensile strength, making it more resistant to breaking under tension.

Which is better, stainless steel or galvanized steel?

Galvanized steel is cost-effective for short to medium-term projects. Stainless steel offers superior corrosion resistance, strength, and minimal maintenance, making it ideal for long-lasting applications.

What are the disadvantages of galvanized steel pipes?

Galvanized pipes can corrode over time, causing leaks, reduced water pressure, discolored water, and potential damage to appliances or property.

Can you use stainless steel fittings on galvanized pipes?

Yes, but proper installation is crucial. Different chemical compositions can cause corrosion at joints, so use correct connectors or anti-corrosion measures.

Conclusion

Galvanized and stainless steel pipe fittings each have distinct advantages for different applications. Galvanized fittings are cost-effective and ideal for standard water or fire systems, while stainless steel fittings provide superior corrosion resistance, durability, and versatility, making them perfect for chemical, marine, food-grade, and industrial piping projects.

When selecting pipe fittings, consider factors like budget, environmental conditions, longevity, maintenance, and compliance to make the right choice and avoid costly issues. For reliable, high-quality pipe fittings in UAE, Mustafa Ashqar Trading LLC is a leading supplier.

Contact MATC today to get the products you need at the best prices and ensure your projects run smoothly.

Read More Experts Insights

Explore expert articles on pipe fittings, valves, and industrial materials to help you choose the right solutions for your next project in UAE.

- Different Types of Rubber Sheets and Their Uses: Helps understand sealing materials used to prevent leakage in flange joints.

- Top Signs Your Hose Needs Replacement Today: Explains how worn hoses can impact pressure systems connected to flanges.

- Different Types of Flanges and Their Uses: Provides insight into flange selection before installation and tightening.

- Seamless vs Welded Pipes: A Complete Guide for Industries: Compares pipe types to ensure correct flange compatibility and performance.

- Step-by-Step Guide to Flange Installation: Flange installation: easy, safe, and precise fitting every time.