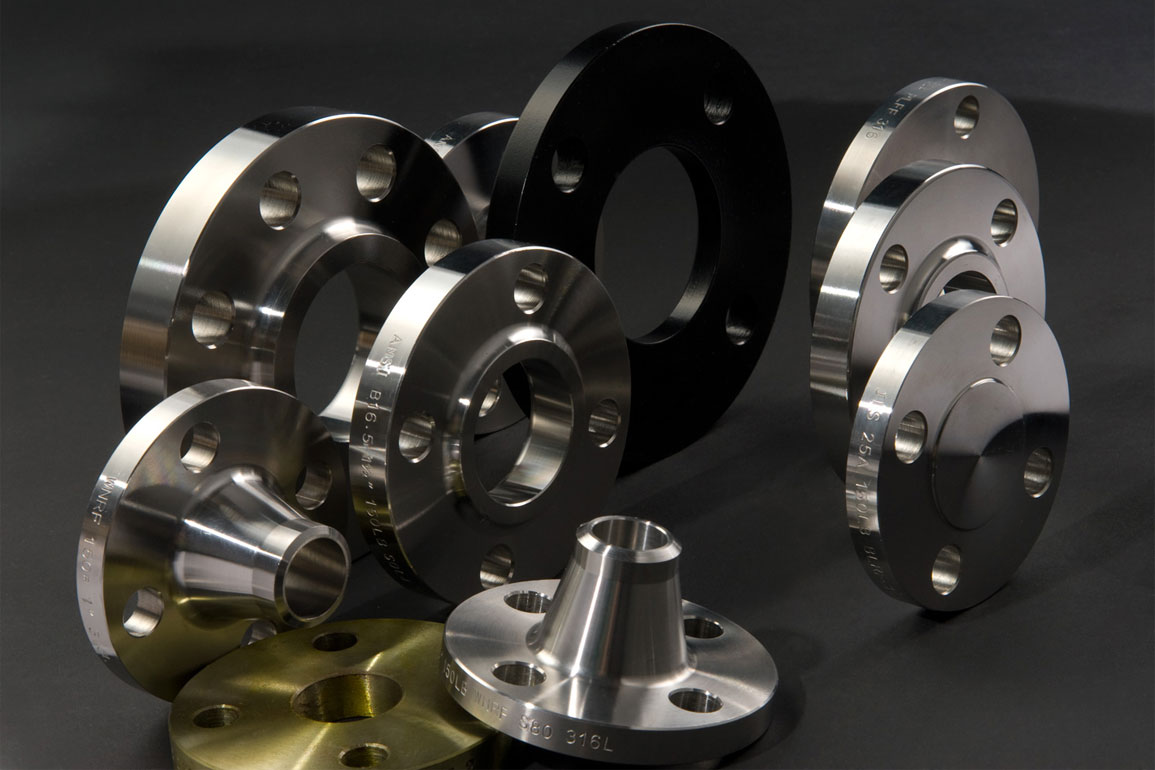

Flanges are essential components in industrial piping systems, providing reliable connections between pipes, valves, pumps, and equipment. They ensure leak-proof performance, structural integrity, and simplify maintenance.

Understanding the types of flanges and their applications is crucial for engineers, maintenance teams, and facility managers to maintain safe and efficient pipeline systems. Flanges are widely used in industries such as oil and gas, petrochemicals, water treatment, power generation, and marine systems.

Following ANSI flange, ASME flange, and DIN flange standards ensures pipelines and equipment remain compatible, durable, and capable of handling varying pressures and temperatures.

What is a Flange and Why It Matters

A flange is a mechanical connector designed to join pipes or attach equipment securely. It provides several advantages:

- Strong and reliable pipeline connections

- Leak-proof sealing with gaskets and bolts

- Easy assembly and disassembly for maintenance or inspection

- Flexibility in connecting different pipe diameters, pressure classes, and materials

In industrial piping, flanges allow smooth operations while providing durability under high-pressure or corrosive environments. Properly selected industrial flanges reduce downtime and prevent leaks.

Common Types of Flanges and Their Applications

Choosing the correct type of flange is key to ensuring pipeline safety and efficiency. Each type has specific benefits for certain industrial flange applications.

Weld Neck Flange

The weld neck flange features a long, tapered hub that distributes stress along the pipe, making it ideal for high-pressure pipelines. It is butt-welded directly to the pipe for a strong, durable connection, often used in chemical plants, refineries, and high-temperature systems.

Slip-On Flange

A slip-on flange is installed by sliding it over the pipe and welding both the inside and outside. This type is suitable for lower-pressure pipelines and general industrial use where alignment flexibility is needed. They are widely used in water distribution systems, HVAC pipelines, and everyday industrial piping projects.

Threaded Flange

Threaded flanges, also called screwed flanges, connect pipes without welding, using internal threads instead. They are ideal for small-diameter pipelines or situations where welding may be hazardous, such as flammable environments. These flanges make installation and disassembly faster and are suitable for temporary or maintenance-heavy piping systems.

Socket Weld Flange

A socket weld flange allows the pipe to be inserted into a recessed area and welded on the outer side, providing strong joints for small-diameter pipelines. These flanges are commonly used in high-pressure chemical processing systems and precision hydraulic pipelines, ensuring alignment and leak-free connections.

Blind Flange

Blind flanges are solid discs that seal the end of a pipeline or vessel, making them essential for pipeline sealing and pressure testing. They are widely applied in industrial plants, chemical processing, and water treatment systems, offering safe closure points for pipelines not currently in use.

Lap Joint Flange

Lap joint flanges consist of a stub end and a backing flange, which allows rotation for easy alignment. This design is particularly useful for pipelines requiring frequent maintenance, such as in food processing, pharmaceuticals, and low-pressure industrial systems.

Specialized Flanges

Industrial pipelines often require specialized flanges for unique applications:

- Orifice flange: Holds orifice plates for accurate flow measurement

- Expander flange: Gradually increases pipe diameter, replacing the need for reducers

- Swivel flange: Allows rotation for proper alignment in complex piping systems

- Elbow flange: Changes pipeline direction while maintaining a secure connection

- Reducing flange: Connects pipes of different diameters

- Split flange: Two-piece flange for repair or retrofitting pipelines

These specialized flanges ensure flexibility, precision, and efficiency in industrial applications.

Flange Standards and Specifications

Compliance with flange standards is critical for safety and compatibility. Considerations include:

- Material: Stainless steel, carbon steel, or alloys

- Pressure rating: ANSI, ASME, DIN

- Flange face type: Raised face, flat face, tongue and groove, or ring joint

- Surface finish: Smooth or serrated for proper sealing

Following the correct flange specifications ensures pipelines perform reliably under all operating conditions.

Flange Maintenance

Proper industrial flange care is essential to maintain efficiency and avoid leaks:

- Inspect regularly for wear, corrosion, and leaks

- Tighten bolts according to recommended torque

- Replace damaged gaskets promptly

- Clean flange surfaces for optimal sealing

Routine pipeline flange inspection reduces operational risks and extends the lifespan of the system.

Selecting the Right Flange

When selecting a flange for a pipeline, consider:

- System pressure and temperature

- Pipe size, material, and flange type

- Maintenance frequency

- Industry standards compliance

Choosing the best flange for a pipeline ensures safe, durable, and leak-proof connections, reducing downtime and increasing efficiency.

AI Overview

Explore different types of flanges, their industrial applications, and standards like ANSI, ASME, and DIN. Learn how weld neck, slip-on, threaded, blind, and specialized flanges ensure safe, leak-proof pipelines.

FAQs

What are the most common types of flanges?

Weld neck, slip-on, threaded, socket weld, blind, lap joint, and specialized flanges like Nipo or expander flanges.

Can slip-on flanges handle high-pressure pipelines?

No. Weld neck and socket weld flanges are preferred for high-pressure applications.

How often should flanges be inspected?

Inspection depends on the pipeline’s usage and pressure, typically quarterly or semi-annually.

Are threaded flanges suitable for industrial pipelines?

Yes, especially for small-diameter, low-pressure, or temporary systems where quick assembly is required.

Conclusion

Industrial flanges are key for safe, efficient, and leak-proof pipeline connections. From weld neck flanges for high-pressure applications to slip-on and threaded flanges for low-pressure systems, each type serves a specific purpose.

Specialized flanges like orifice, swivel, or reducing flanges address unique industrial challenges. Following proper flange standards, careful selection, and regular maintenance ensures operational safety, efficiency, and longevity.

Browse our complete range of industrial flanges and select the ideal solution for your pipeline and industrial piping needs today.

Read More Experts Insights

Explore expert articles on pipe fittings, valves, and industrial materials to help you choose the right solutions for your next project in the UAE.

- Common Pipe Fitting Failures: Causes & Prevention Tips – Learn about frequent pipe fitting failures and how to prevent them with proper materials and maintenance.

- Seamless vs Welded Pipes: A Complete Guide for Industries – Seamless or welded pipes: Expert guide for reliable industrial choices.

- Why High‑Zinc GI Pipes Are Trending in UAE Construction – High‑Zinc GI Pipes: The Trending Choice in UAE Construction.

- Understanding Lüdecke Couplings and Their Uses – Enhance Pipe Strength, Durability, and Cost-Efficiency in Construction.

- Brass Hex Nipple BSP vs NPT: Uses & Sizing for Dubai Projects – Understand the difference between BSP and NPT threads and how to choose the right type for your Dubai projects.