In the city of Dubai, where construction and industry never stop working, the demand for reliable plumbing and industrial components is always high. Among these, brass fittings stand out as a top choice for high-pressure applications.

Let’s explore why brass fittings in Dubai are so popular and why they are the go-to option for many projects in the UAE.

The Strength of Brass

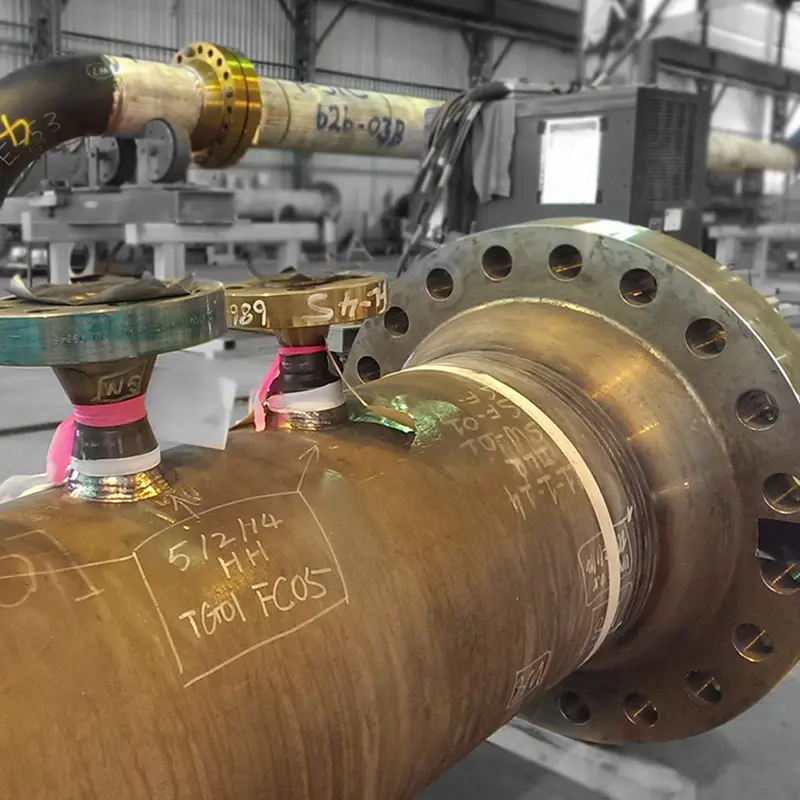

Brass is a tough material, and it’s an alloy of copper and zinc, which gives it unique properties. This combination makes brass strong enough to handle high pressures. In Dubai’s scorching heat and demanding industrial environments, this strength is crucial.

Brass fittings can withstand the pressure without cracking or breaking. This reliability is why many builders and engineers in Dubai prefer brass over other materials.

Corrosion Resistance in Dubai’s Climate

Dubai’s weather can be harsh, and the heat and humidity can cause many materials to corrode quickly, but brass is different. It resists corrosion naturally, and this resistance means brass fittings last longer in Dubai’s climate.

They don’t rust or deteriorate like some other metals might. This durability saves money and time on replacements and repairs.

Versatility in Applications

Brass fittings are versatile, and they work well in many different settings. From residential plumbing to industrial machinery, brass fits the bill. In Dubai’s diverse construction landscape, this versatility is valuable.

Whether it’s a luxury hotel or manufacturing plant, brass fittings can handle the job. This wide range of uses makes them a favorite among brass fittings suppliers in the UAE.

Simple to Use

Brass is a soft metal compared to some others, and this softness makes it easier to work with. Plumbers and technicians can shape and adjust brass fittings as needed.

In Dubai’s fast-paced construction industry, this flexibility is a big advantage. It allows for quicker installations and modifications. This ease of use is another reason why brass fittings in Dubai are so popular.

Cost-Effective in the Long Run

At first glance, brass might seem more expensive than some alternatives. But it’s important to think long-term. Brass fittings last longer and need less maintenance. In Dubai’s competitive market, this durability translates to cost savings over time.

Businesses and homeowners end up spending less on replacements and repairs. This long-term value is a key selling point for brass fittings suppliers in the UAE.

Temperature Resistance

Dubai is known for its extreme temperatures, and brass fittings can handle these temperature swings well. They don’t expand or contract as much as some other materials.

This stability is crucial in high-pressure systems. It means fewer leaks and a more reliable performance. In Dubai’s climate, this temperature resistance is a significant advantage.

Availability in Dubai

Dubai is a major hub for construction and industry. As a result, brass fittings suppliers in the UAE are plentiful. This availability means that getting the right brass fittings for a project is usually quick and easy.

The competitive market also helps keep prices reasonable. This ready supply is a big benefit for project managers in Dubai.

Conclusion

Brass fittings consistently demonstrate their worth in the demanding environment of Dubai. Brass has many advantages, including aesthetic appeal and resistance to corrosion. The availability of brass fitting suppliers in the UAE ensures a steady supply for Dubai’s ongoing projects.